Engine Reconditioning

The heart of everything we do

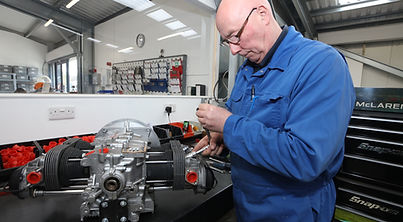

Our engine building process is systematic and precise. Our engine builders, technicians and machinists have been trained with us and are extremely experienced working specifically with VW classic engines.

Several staff have been building aircooled VW's and advising customers with us for over 40 years!

We're very proud of our staff, their dedication to us and their efforts in making our product and service the best it can be.

Constantly questioning scope for development, we invest heavily in sourcing the best components and have very strict quality control procedures throughout our production ensuring our engines are not only the best quality available but remain cost effective.

All machining and building is completed in house to ensure exact standards and quality controls are adhered to as per the original manufacturers VW specifications in Wolfsburg and Hanover Germany.

No automated machinery necessary here, machines are operated manually, as it should be, by the experience of our engineers, checked and double checked.

Our working environment is clean and organised and we believe this helps us produce a top quality product. Unsure? Stop by anytime and see for yourself.

_JPG.jpg)